C01D Technology

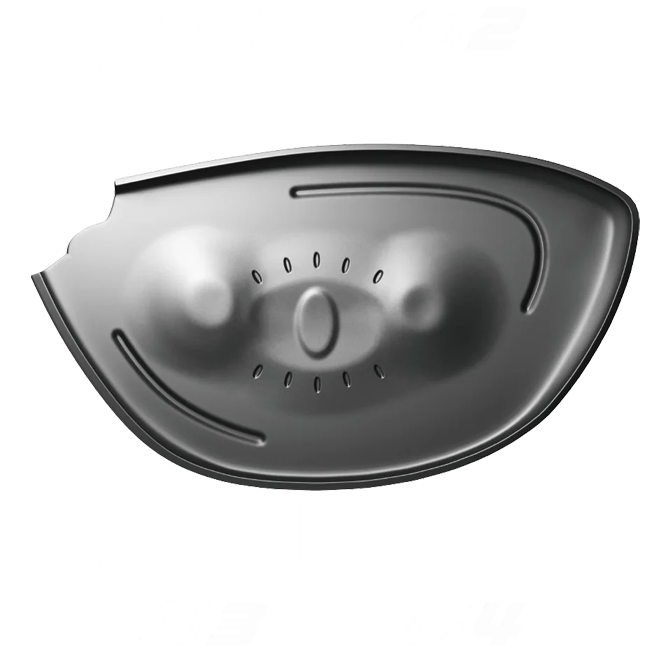

The QUATTRO FORGED FACE with 4 technologies combined

Four proprietary technologies are incorporated into a single cup face to expand area with stable and high rebound. The driver delivers a pleasant feel and powerful performance, all while providing bounce and capturing the ball.

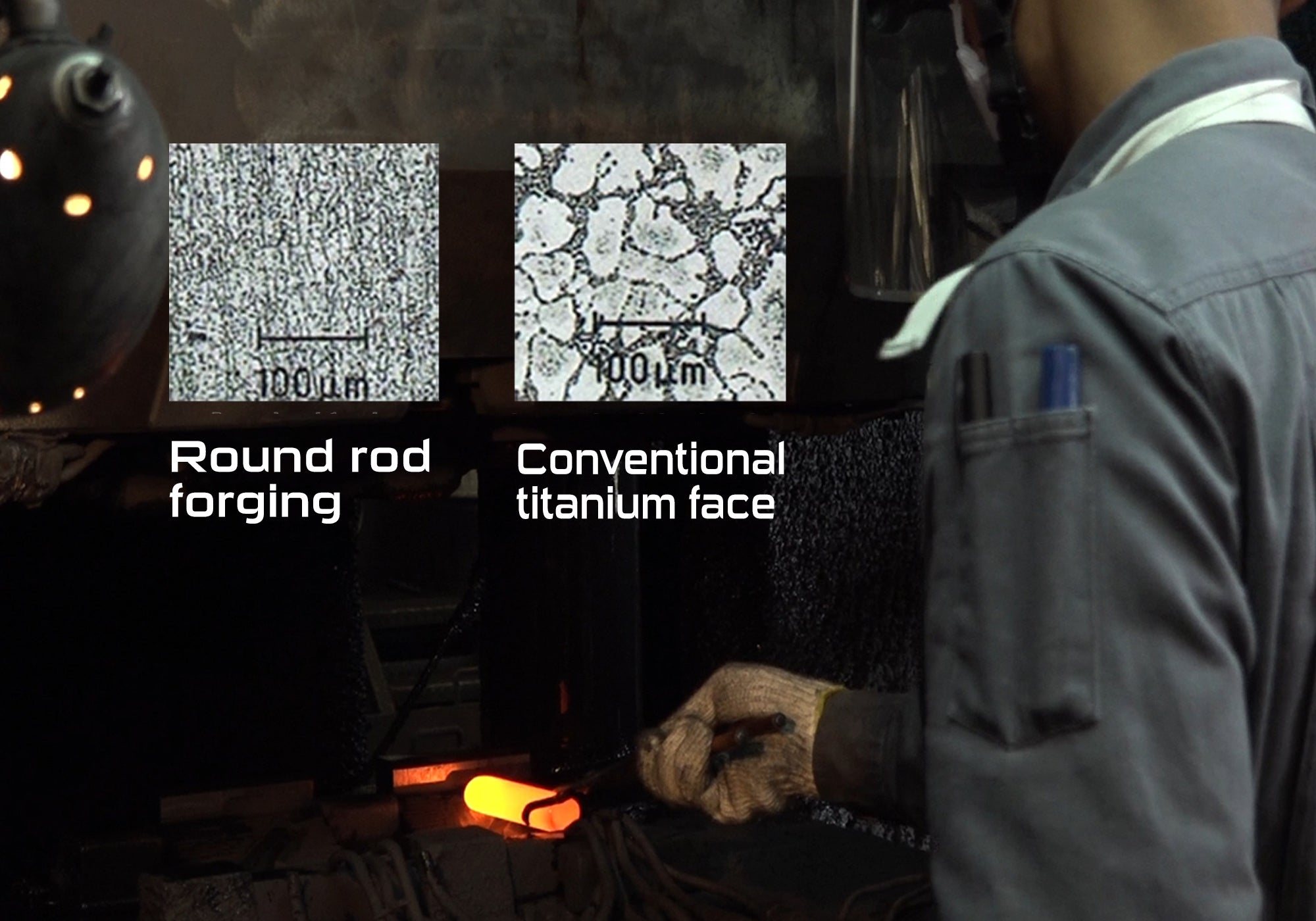

ROUND rod forging that produces exceptionally strong and dense metalic structure

Round rod forging that produces exceptionally strong and dense metallic structure *Revolutionary In contrast to conventional drivers with a face made of rolled titanium sheet material, the C01D incorporates round rod forging, PROTOCONCEPT’s innovative technology. The metal structure becomes very dense, improving tensile strength, hardness, and tenacity.

Through incorporating the round rod forging method, the titanium crystals have a more dense and uniform structure, creating a forged line (metal flow) in which metal particles are aligned and improving strength while providing a soft yet secure feel when hitting.

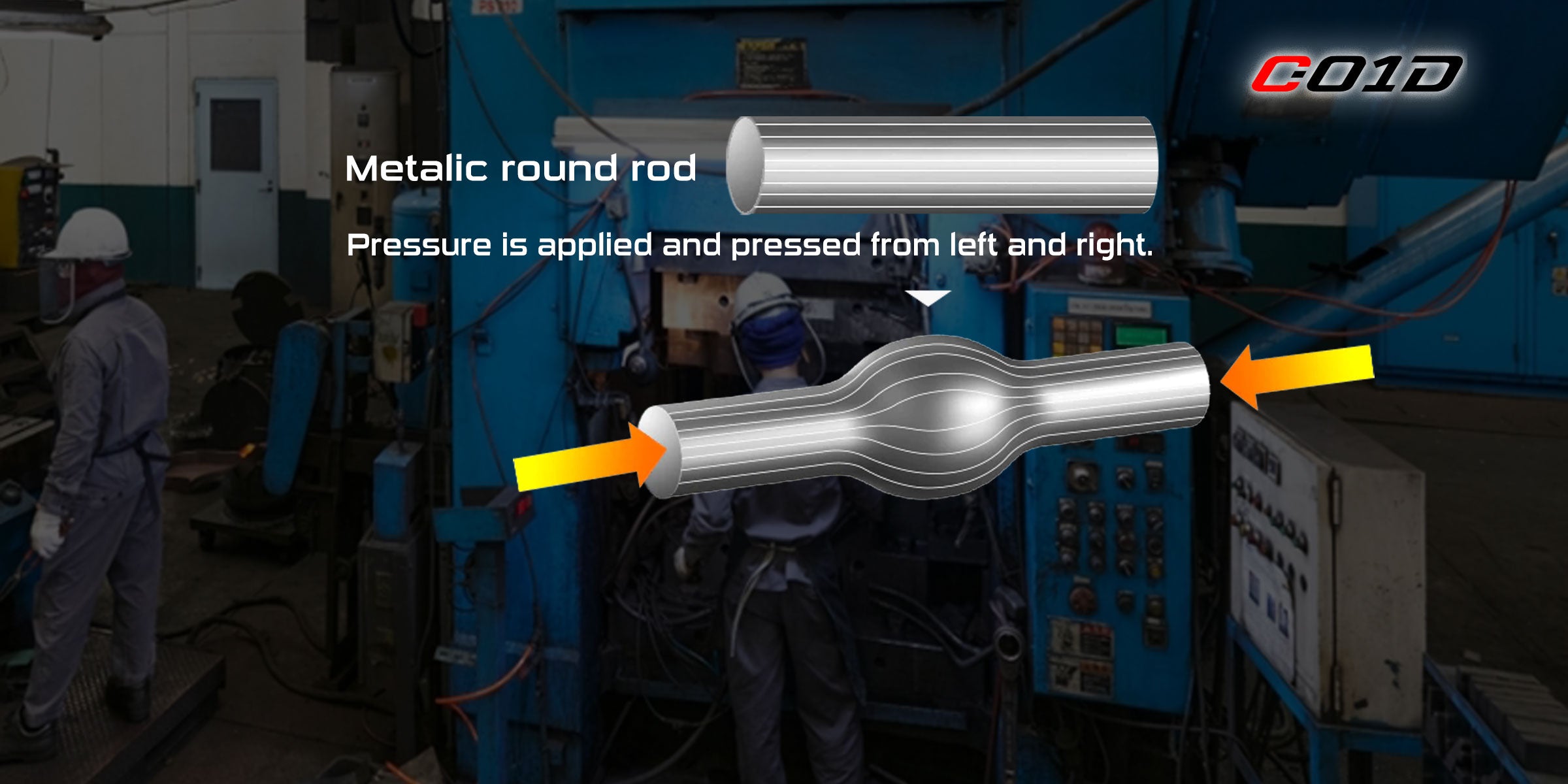

#01 Round rod forging

Forged line created with Spheres

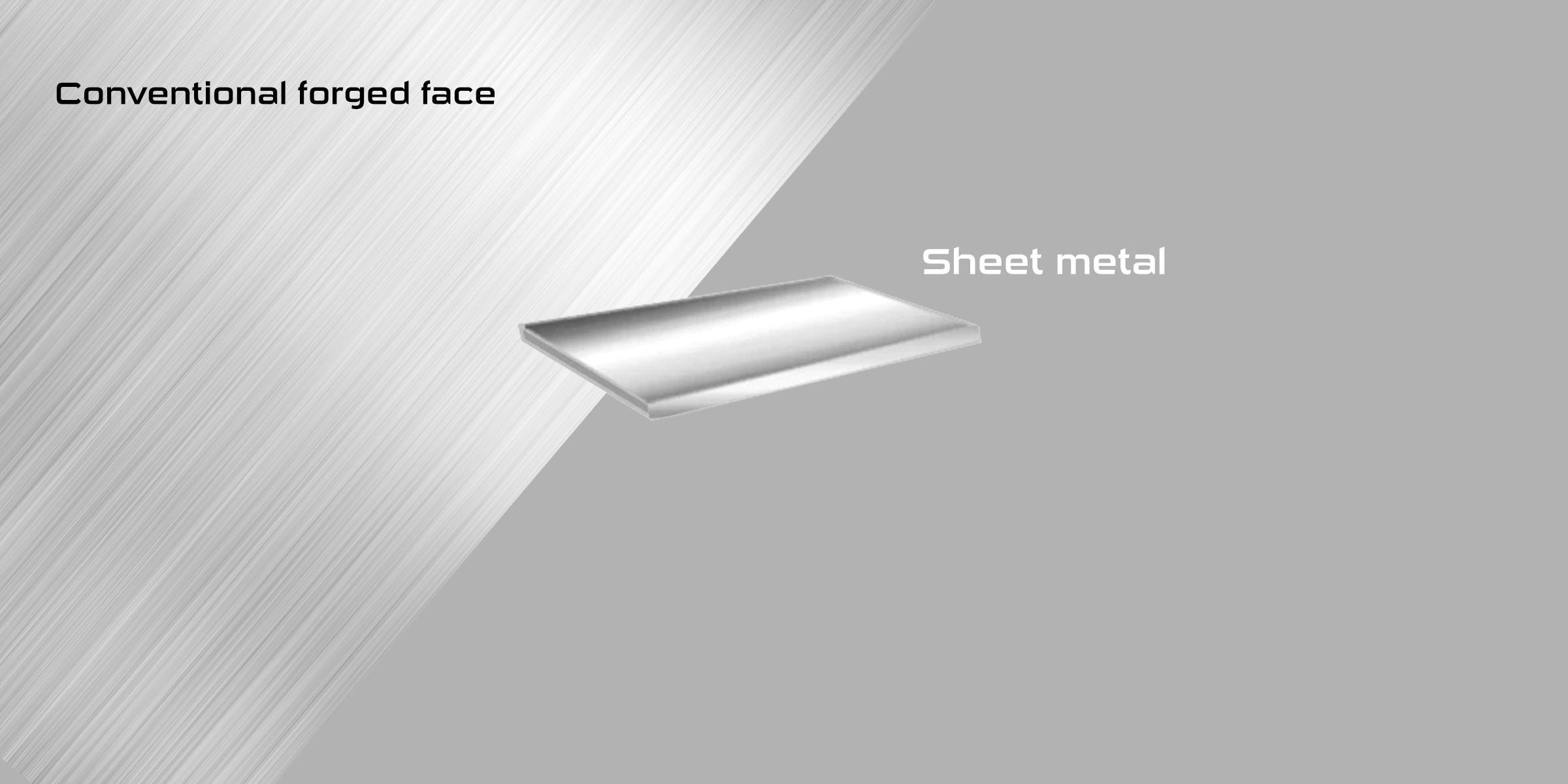

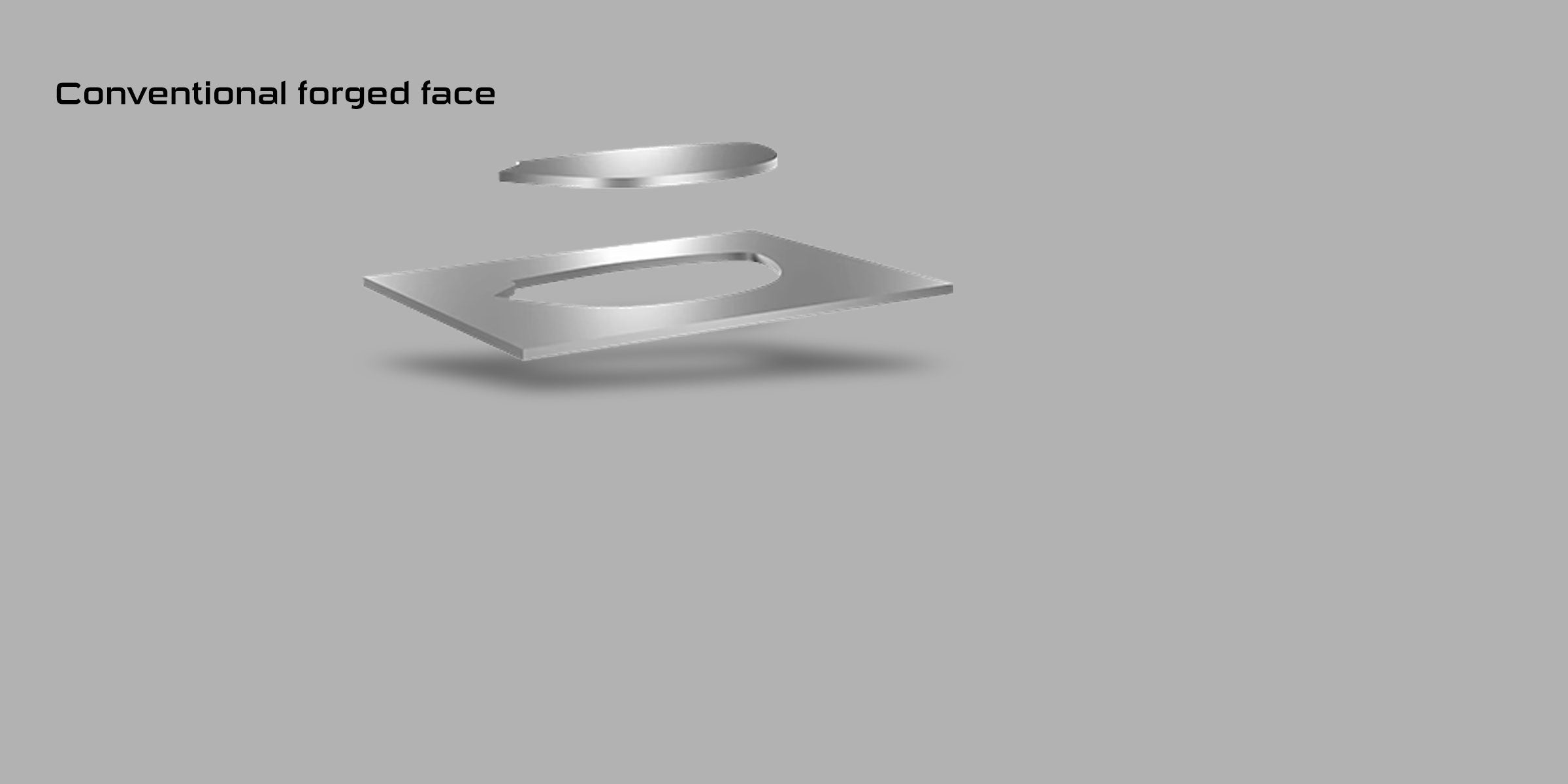

In general, because faces are made by press-forming sheet titanium called “rolled material”, forged lines cannot be produced. They need to be made thicker to maintain hardness and strength.

α/β titanium round rods with superior strength are used. Only the middle part is heated and pressurized and compressed at a high pressure of 1,600 tons, a unique process that makes the middle part of the round bar into a large, bulging sphere. The forged lines gather in the center, resulting in a denser metallic structure.

#02 Roughing

Outstanding technology in high-precision press work

Sheet titanium are produced through the rolling process. The microstructure is not as dense or strong as that of the round rod forging process, and no forged lines are created.

High press pressure is used to form high-strength titanium material, which requires technology. The metallic structure is forged to produce initial velocity performance and secure feel when hitting. The reason for adopting round bar forging instea of conventionally used plates is to make the titanium's metallic structure denser and uniform, and to create forged lines that deliver good feel when hitting the ball. This method attains high strength and durability but requires advanced technology for manufacturing, including for temperature control and pressurization method.

#03 Finish FOrging

The excess surrounding parts that were molded into the cup face in the previous process are removed. Due to the high precision of the manufacturing process, there is little margin needing removal.

#04 Correcting

The final pressing is done with a load of 500 tons.

The complex shapes with thickness deviation can be produced as designed with high-precision forging, which minimizes errors in thickness and weight and reduces the need for polishing work to the very least.

#5 Face Polishing

High precision face crafted with no "trimming down" required

The weld marks made after welding the face are polished by hand. The most common method is to make them large in advance and scrape afterwards. This causes large variations in CT values due to the manual scraping.

High press pressure is used to form high-strength titanium material, which requires technology. The metallic structure is forged to produce initial velocity performance and secure feel when hitting. The reason for adopting round bar forging instea of conventionally used plates is to make the titanium's metallic structure denser and uniform, and to create forged lines that deliver good feel when hitting the ball. This method attains high strength and durability but requires advanced technology for manufacturing, including for temperature control and pressurization method.

#6 Welding

A common manufacturing method in which the face of plates is welded to the body.Manual polishing is needed to even out the face surface area. This polishing process tends to cause individual differences in performance such as rebound. The heat from the welding may also affect property.

Unlike the conventional method of welding inside the face, the cup face is welded at the outer body. Through this method, there is no need to shave the face portion in the final polishing process, and differences among finished products due to polishing can be reduced. There will also be no property changes triggered by the high temperatures from welding.

#7 Completion

So-called “good” and “bad” results tend to occur because individual differences in manufacturing inevitably scale up.

With precise forged lines, the completed product achieves sophisticated rebound performance just barely within the rules with artistic accuracy. The loft, lie angle, FA and CT are inspected for all products.In particular, the CT is inspected at 11 points of the face, and all products are finished with values that just within regulations.